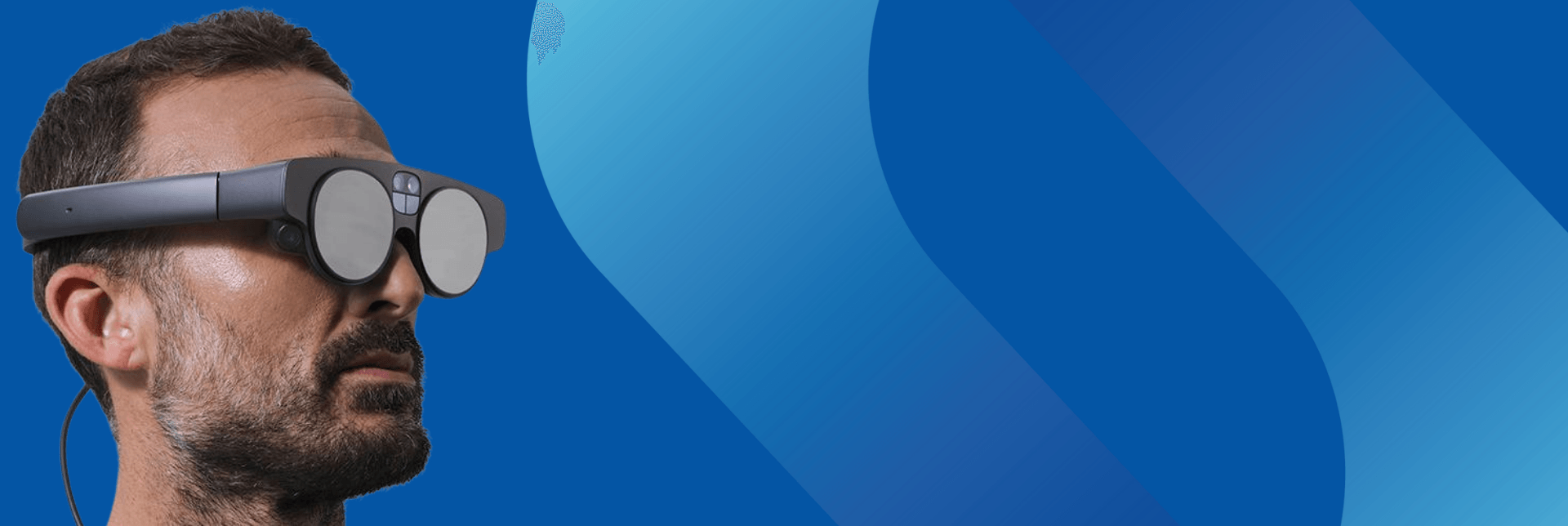

Magic Leap 2 Case Studies

Savings in Time and Cost

Book a Test Drive to see if Magic Leap 2 is right for your business

PBC Linear Case Study

With the use of Magic Leap 2, PBC Linear managed to save an incredible 97% in training resources, resulting in some fantastic savings on costs as well as time. We explore exactly how they did this below...

How did they do it?

Lets start with the problem:

-

Experienced machinists traditionally trained new machinists and this took 6 weeks. 6 weeks of downtime per experience machinists is very expensive.Watch now: Tim LeCrone Clip 1 - The Problem video clip

-

New employees are often experiencing Augmented Reality for the first time, so what does the adoption and savings look like?

-

The savings are immediate in reduced training time, meaning- Less Experienced machinist downtime- Less Training time for the new employee- Less training manager time organising training and executingWatch now: Tim LeCrone - Savings and Efficiency areas

-

The savings don't just stop with the people... 20% less scrap and wastage makes a compelling cut in manufacturing costs, making PBC Linear much more efficient

The savings, numbers and return on the Magic Leap investment are compelling:

-

$7,200 saving on experienced machinist training costs

-

$5,760 saving on machinist training time per machinist

-

$6,080 saving on training managers time

-

Savings per machinist $19,040

-

Payback in Magic Leap 2 investment 5.7x on one machinist!

Test Drive a Magic Leap 2 today

Full Video below (less than 2 minutes viewing)

Magic Leap 2 "Field of View" Example

Watch the Magic Leap 2 v Microsoft HoloLens v Realwear 500 - 'Field of View" comparison below.

Want to see the comparison for yourself? Book your Magic Leap 2 Test Drive here

Magic Leap Useful Links -What you should know

- Magic Leap 2 Regulatory / Operating Environments

- Magic Leap 2 Download Centre

- Magic Leap 2, HoloLens 2 and Augmented Reality explained.

- Magic Leap 2 FAQ's

- Magic Leap 2 vs Microsoft HoloLens 2 - Field of View Video

- Magic Leap 2 and SentiAR 3D Visualisation Software

- Magic Leap 2 - Developers Guide

- Magic Leap Use Cases

- Magic Leap 2 Case Studies

- 3 exciting use cases for Magic Leap 2

- Magic Leap , Siemens and the Javits Centre

- Magic Leap 2 and Manufacturing Training with Manifest Software.

- Magic Leap 2 Medical Holodeck - Training and Operating Use Cases

- Magic Leap 2 and Healthcare